Specialist in

ZEROTEC, Galician company founded in 2007, which despite the business instability of recent times, has been able to establish itself and position itself in the market, thanks to the perseverance and great effort of its entire human team .

ZEROTEC starts its activity as a boiler company, through the manufacture and installation of all kinds of metal products. Our great versatility and high professional potential allow us to undertake projects of all kinds and for the most diverse industrial sectors, among which we can mention AUTOMOTIVE, FOOD, PHARMACEUTICAL, CONSTRUCTION, PAPER, NAVAL and INDUSTRIAL in general, as well as work for individuals .

For this we have facilities of approximately 1.000 m2, located in the surroundings of Vigo, various machinery and a highly qualified staff with great experience and professionalism. We also have our own Technical Office, which allows us to provide customers with turnkey projects, including studio e development Engineering, manufacturing, installation y start up.

Quality

Since our inception, we have been committed to quality product quality and excellence in service, as the key to success to consolidate ourselves in an increasingly competitive and globalized market.

We intend to provide a comprehensive service to our customers and in return obtain a FULL SATISFACTION of them. Our ultimate goal is continuous improvement, which is why we work every day to improve our internal processes, as well as to implement new technologies that allow us to achieve this goal.

In August 2014 ZEROTEC is certified under the standard EN 1090-1:2009: Execution of steel and aluminum structures. Part 1 Standard that accredits the contractor for the construction of Steel Structure Components y obliges the CE marking of any product manufactured to be incorporated permanently in construction works, both in building and civil works.

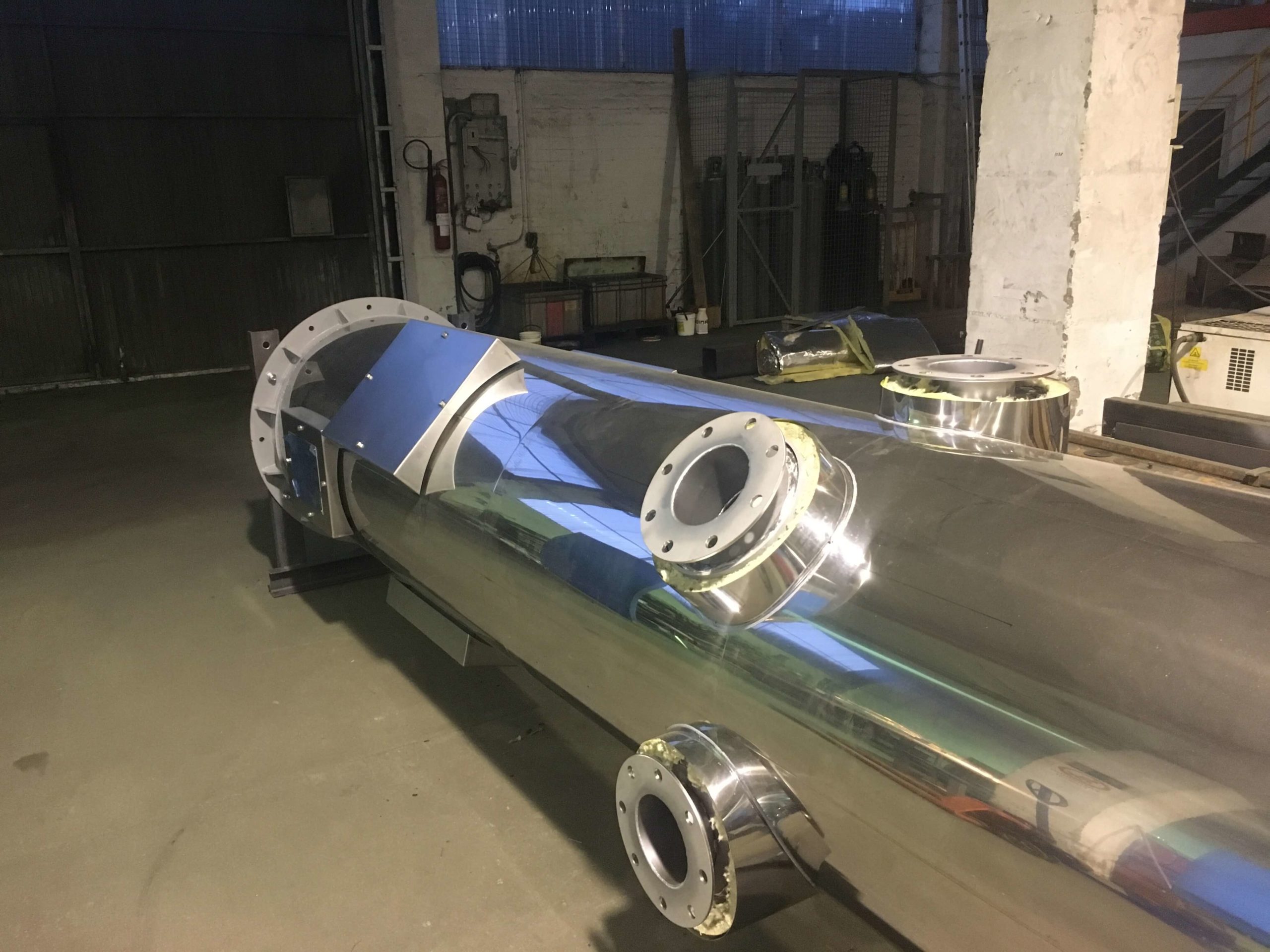

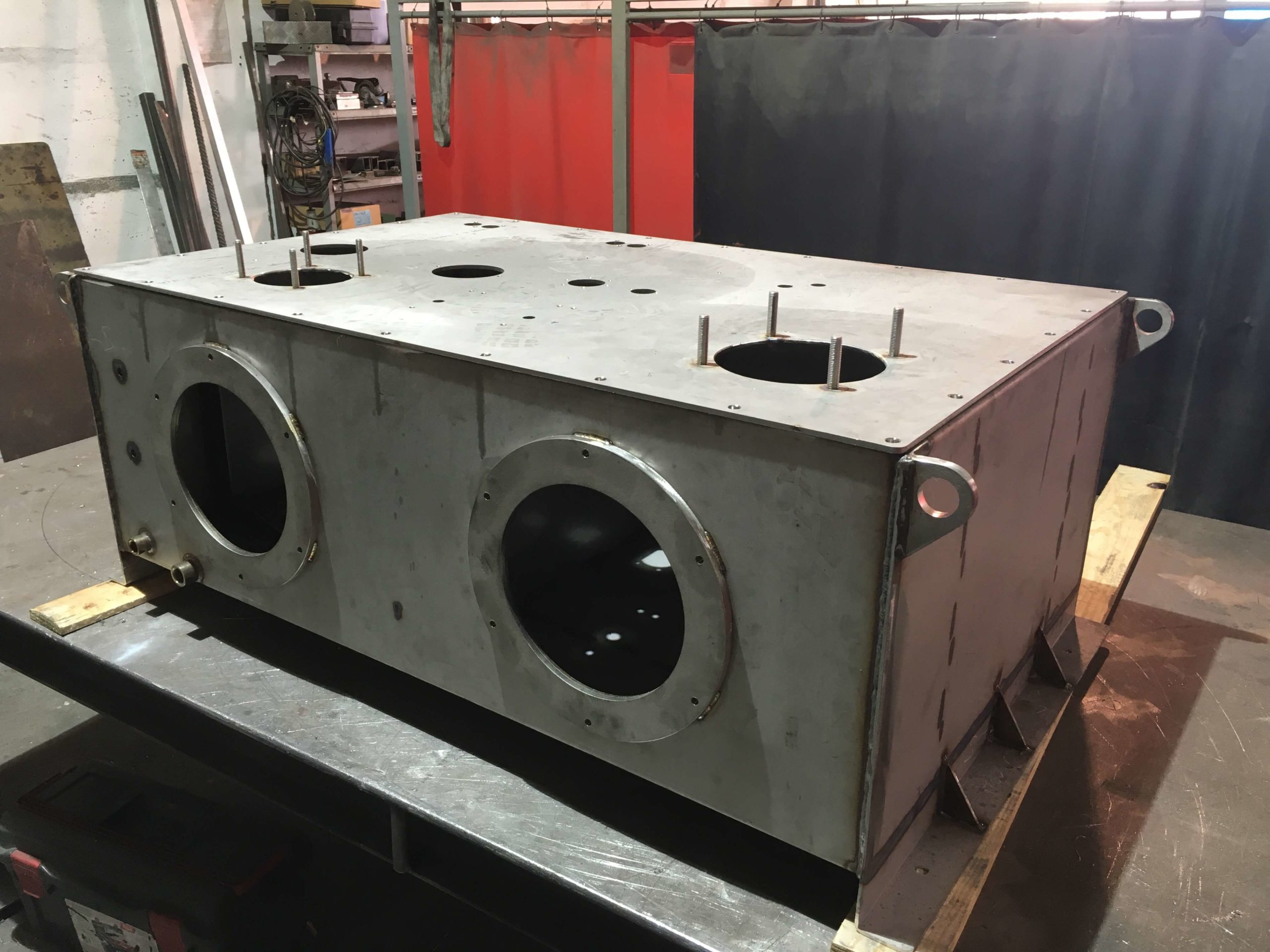

ZEROTEC was born as a boiler company, therefore carbon steel, stainless steel and aluminum are common raw materials, whether in sheet metal, profiles and pipes in general. We also work with other types of metallic materials such as foundries, forges, copper, brass and titanium. We also carry out cutting, folding and welding work on plastic materials, while we combine our production with other non-metallic materials such as glass or wood.

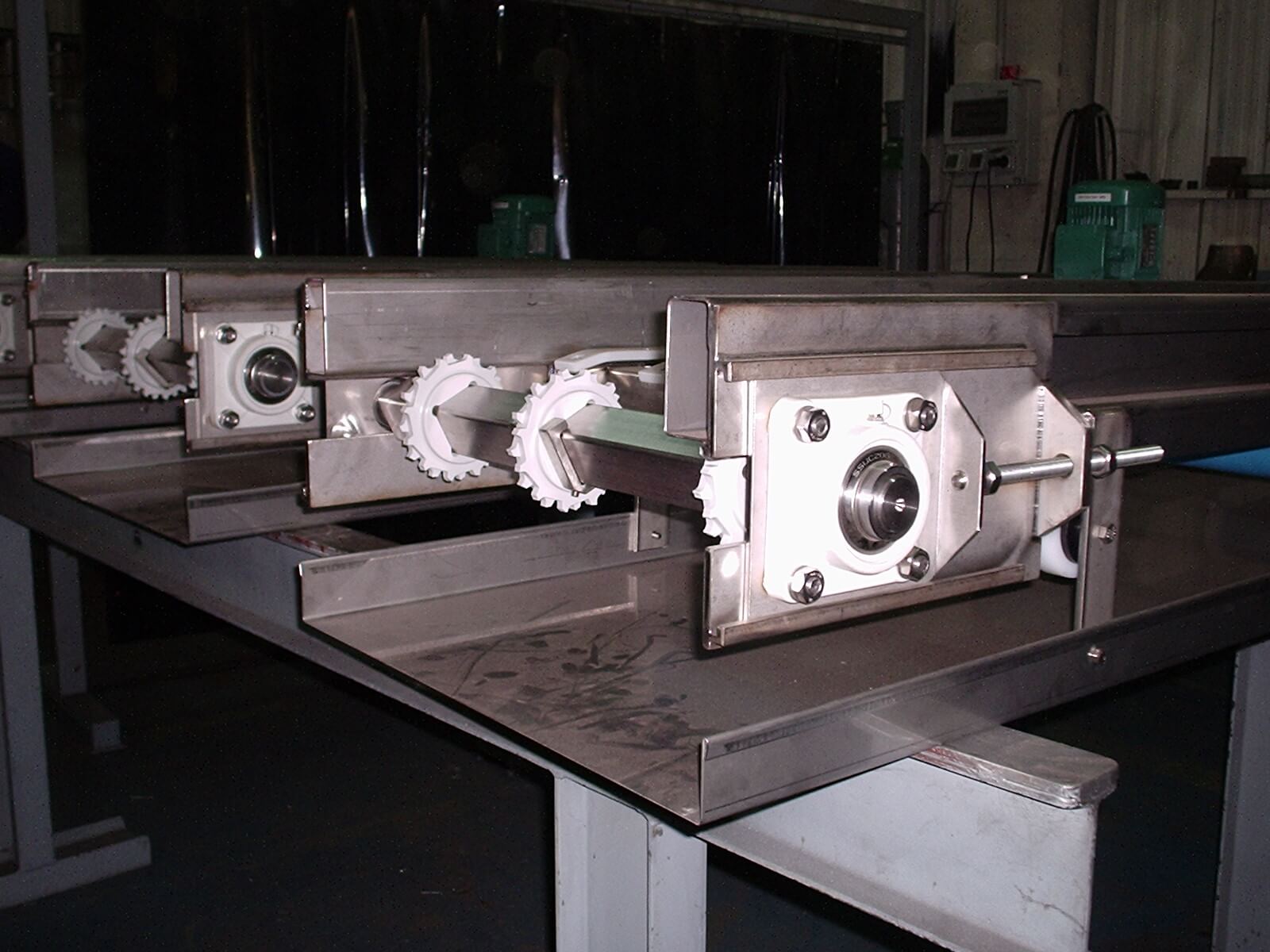

Machine design

We develop prototypes just as we carry out design, manufacturing, installation and commissioning of machines or mechanisms for different sectors such as the automotive, food or pharmaceutical industries.

Through these machines we offer exclusive solutions for each particular situation, automating processes or improving existing ones, which translates for our clients into a reduction in their costs and an improvement in their productivity.

Fabrication and installation

We offer our clients a comprehensive service that includes design, manufacturing, installation and commissioning of each and every one of the projects we undertake.

Our high level of demand and strict internal controls mean that all our products are of high quality and have a perfect finish, managing to satisfy the needs of our customers at all times.

Likewise, and in those cases in which the project requires it, we also take care of the installation and start-up, counting on a highly experienced and highly professional team.

Stainless Works

We are specialists in working with stainless steel. For this reason, part of our production is dedicated to DECORATION, through the manufacture of different elements for commercial or residential use, such as:

- Stairs in stainless steel

- Stainless steel railings

- Halls in stainless steel

- Labels and logos

And in general any product or piece of decoration, using stainless steel as a raw material, either alone or in combination with materials of a different nature such as glass or wood.

We collaborate with important international companies dedicated to urban furniture, taking advantage of the great versatility and facility that our staff possesses when working with materials of a different nature.